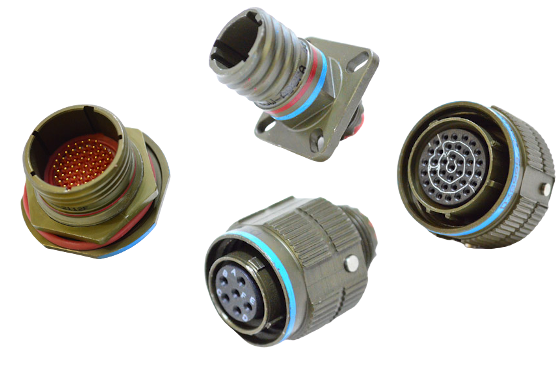

D38999 series III

Although R.E.C. do not build QPL D38999 connectors, we have partnered with manufaturers and assemblers so that we are able to offer this series quickly and affordably.

Below you will find all the information needed to order these connectors. If you need any help, just get in touch.

Contact layouts according to MIL-STD-1560 – MORE INFO

Only qualified M39029 contacts may be used.

Unlike in 26482 or 5015 part numbers, the backshell information is not specified in D38999 part numbers. Please jump to the backshell section for our guide on choosing one, as plugs will need to be protected in some way. All receptacles also have accessory threads if shielding, strain relief or environmental protection is needed.

See below for a breakdown

OVERVIEW

CONTACT TERMINATION: crimp

MATING STYLE: threaded

EQUIVALENTS: EN3645, BACC63CT/CU, BACC63DB/DC

| SERIES: | SHELL STYLE | CLASS/PLATING | SHELL SIZE | LAYOUT | CONTACT GENDER | KEYWAY | ||||

| D38999 | /20 | square flange receptacle | e.g. F | A | 9 | e.g. 35 | P | pin | N | standard |

| /24 | jam-nut receptacle | JUMP TO CLASS/PLATING | B | 11 | JUMP TO LAYOUTS | S | socket | A | ||

| /26 | plug | C | 13 | A | without pin contacts | B | ||||

| D | 15 | B | without socket contacts | C | ||||||

| E | 17 | D | ||||||||

| F | 19 | E | ||||||||

| G | 21 | |||||||||

| H | 23 | |||||||||

| J | 25 | |||||||||

[/ultimate_info_table]

SHELL STYLES

PLUGS

RECEPTACLES

CONNECTOR CLASS/PLATING

| Reference | Shell material | Plating | Salt spray | Temperature range |

| W | aluminium | cadmium olive drab | 500 hrs | -65°c + 175°c |

| F | aluminium | electroless nickel | 48 hrs | -65°c + 200°c |

| Z | aluminium | black zinc nickel | 500 hrs | -65°c + 200°c |

| S | stainless steel | passivated surface | 500 hrs | -65°c + 200°c |

| K | stainless steel | electroless nickel | 500 hrs | -65°c + 200°c |

| M | composite | electroless nickel | 2000 hrs | -65°c + 200°c |

| J | composite | cadmium olive drab | 2000 hrs | -65°c + 175°c |

| N | stainless steel | electro deposited nickel | 500 hrs | -65°c + 200°c |

| Y | stainless steel | passivated surface | 500 hrs | -65°c + 200°c |

| Layout | Shell size | Contacts | 22D | 20 | 16 | 12 | 10 | 8 |

| A35 | 9 | 6 | 6 | |||||

| A98 | 9 | 3 | 3 | |||||

| B2 | 11 | 2 | 2 | |||||

| B4 | 11 | 4 | 4 | |||||

| B5 | 11 | 5 | 5 | |||||

| B35 | 11 | 13 | 13 | |||||

| B98 | 11 | 6 | 6 | |||||

| B99 | 11 | 7 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_heading=”C-D”]

| Layout | Shell size | Contacts | 22D | 20 | 16 | 12 | 10 | 8 |

| C4 | 13 | 4 | 4 | |||||

| C8 | 13 | 8 | 8 | |||||

| C35 | 13 | 22 | 22 | |||||

| C98 | 13 | 10 | 10 | |||||

| D5 | 15 | 5 | 5 | |||||

| D15 | 15 | 15 | 14 | 1 | ||||

| D18 | 15 | 18 | 18 | |||||

| D19 | 15 | 19 | 19 | |||||

| D35 | 15 | 37 | 37 | |||||

| D97 | 15 | 12 | 8 | 4 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_heading=”E-F”]

| Layout | Shell size | Contacts | 22D | 20 | 16 | 12 | 10 | 8 |

| E6 | 17 | 6 | 6 | |||||

| E8 | 17 | 8 | 8 | |||||

| E26 | 17 | 26 | 26 | |||||

| E35 | 17 | 55 | 55 | |||||

| E99 | 17 | 23 | 21 | 2 | ||||

| F11 | 19 | 11 | 11 | |||||

| F28 | 19 | 28 | 26 | 2 | ||||

| F30 | 19 | 30 | 29 | 1 | ||||

| F32 | 19 | 32 | 32 | |||||

| F35 | 19 | 66 | 66 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_heading=”G-H”]

| Layout | Shell size | Contacts | 22D | 20 | 16 | 12 | 10 | 8 |

| G11 | 21 | 11 | 11 | |||||

| G16 | 21 | 16 | 16 | |||||

| G35 | 21 | 79 | 79 | |||||

| G39 | 21 | 39 | 37 | 2 | ||||

| G41 | 21 | 41 | 41 | |||||

| G75 | 21 | 4 | 4 Twinax | |||||

| H21 | 23 | 21 | 21 | |||||

| H32 | 23 | 32 | 32 | |||||

| H35 | 23 | 100 | 100 | |||||

| H53 | 23 | 53 | 53 | |||||

| H55 | 23 | 55 | 55 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_heading=”J”]

| Layout | Shell size | Contacts | 22D | 20 | 16 | 12 | 10 | 8 |

| J4 | 25 | 56 | 48 | 8 | ||||

| J8 | 25 | 8 | 8 Twinax | |||||

| J11 | 25 | 11 | 2 | 9 | ||||

| J19 | 25 | 19 | 19 | |||||

| J20 | 25 | 30 | 10 | 13 | 4 Coax | 3 Twinax | ||

| J24 | 25 | 24 | 12 | 12 | ||||

| J29 | 25 | 29 | 29 | |||||

| J35 | 25 | 128 | 128 | |||||

| J43 | 25 | 43 | 23 | 20 | ||||

| J46 | 25 | 46 | 40 | 4 | 2 Coax | |||

| J61 | 25 | 61 | 61 | |||||

| J90 | 25 | 46 | 40 | 4 | 2 Twinax |

[/ultimate_info_table]

| Size | Pin | Socket |

| 22D | M39029/58-360 | M39029/56-348 |

| 20 | M39029/58-363 | M39029/56-351 |

| 16 | M39029/58-364 | M39029/56-352 |

| 12 | M39029/58-365 | M39029/56-353 |

| 12 coax | M39029/28-211 | M39029/75-416 |

| 12 coax | M39029/102-558 | M39029/103-559 |

| 10 | M39029/58-528 | M39029/56-527 |

| 8 coax | M39029/60-367 | M39029/59-366 |

| 8 twinax | M39029/90-529 | M39029/91-530 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_sub_heading=”METALLIC INSERTION TOOL”]

| Size | Insertion | Extraction |

| 22D | M81969/8-01 | M81969/8-02 |

| 20 | M81969/8-05 | M81969/8-06 |

| 16 | M81969/8-07 | M81969/8-08 |

| 12 | M81969/8-09 | M81969/8-10 |

| 12 coax | M81969/8-09 | M81969/8-10 |

| 12 coax | M81969/8-09 | M81969/8-10 |

| 10 | M81969/8-09 | M81969/8-10 |

| 8 coax | M81969/8-13 | M81969/8-14 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_sub_heading=”CRIMP TOOL AND POSITIONER”]

| Size | Crimp tool | Pin positioner | Socket positioner |

| 22D | M22520/2- 01 | M22520/2-09 | M22520/2-07 |

| 20 | M22520/1- 01 | M22520/1-04 | M22520/1-04 |

| M22520/2-01 | M22520/2-10 | M22520/2-10 | |

| 16 | M22520/1-01 | M22520/1-04 | M22520/1-04 |

| 12 | M22520/1-01 | M22520/1-04 | M22520/1-04 |

| 12 Coax Inner | M22520/2-01 | M22520/2-34 | M22520/2-34 |

| 12 Coax Outer | M22520/31-01 | M22520/31-02 | M22520/31-02 |

[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_sub_heading=”FILLER PLUGS AND INSERTION TOOL”]

| Size | Filler plug | Insertion/removal tool |

| 22D | MS27488-22-1 | M81969/14-01 |

| 20 | MS27488-20 -1 | M81969/14-10 |

| 16 | MS27488-16 -1 | M81969/14-03 |

| 12 | MS27488-12-1 | M81969/14-04 |

| 10 | M85049/81-10 | M81969/14-05 |

| 8 coax | MS27488-8-1 | M81969/14- 06 |

| 8 twinax | MS27488-8-1 | M81969/14-12 |

[/ultimate_info_table]

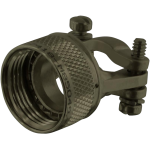

OVERVIEW

D38999 part numbers do not specify a backshell. Therefore, if any kind of ingress protection, strain relief, shielding, or any other form of protection or enhancement are required, a backshell must be bought separately. This means that plugs will definitely need a backshell.

The military designation for backshells is M85049, although commercial variants are often used. The platings available under the military designation are cadmium olive drab (W), electroless nickel (N), black anodised (A) and black zinc nickel (Z), as well as others which are specific to alternative materials (such as stainless steel and composite.) Note that black anodised (A) is available on military heat shrink boot adapters (/88, /89, /90.)

The most common types of backshells used with D38999 connectors are cable clamps and EMI shielded heat shrink boot adapters. Cable clamps are low cost and usually bought under the military designation M85049/38.

Shielded heat shrink boot adapters are more commonly bought under commercial part numbers, such as Polamco 91 or BT series. The military designation is M85049/88, although the military version includes a self-locking mechanism that is not standard to most commercial equivalents. The shielding/braiding is usually terminated onto the backshell using a M85049/128-3 strap (tooling required) or a constant force spring.

R.E.C. is able to manufacture all of the above. Our official circular accessories series will be launched soon. In the meantime you can enquire on an individual basis, or we can help you source any other manufactuer’s version.

MOST COMMON EXAMPLES

| Basic part number | Locking? | Shell size | Plating | |||

| M85049/38 | Straight | – | non-self-locking | e.g. 11 | W | cadmium olive drab |

| M85049/39 | 90 degree | N | self-locking, non-detented | A | black anodised | |

| S | self-locking, detented | N | electroless nickel | |||

“N” Self-Locking, Non-Detented, utilizes an internal captivated anti-decoupling device (Self-Seating) with no audible clicking mechanism.

“S” Self-Locking, Detented, utilizes an audible detented anti-decoupling device.[/ultimate_info_table][ultimate_info_table design_style=”design04″ color_scheme=”gray” package_heading=”HEAT SHRINK BOOT ADAPTER PART NUMBERING” package_sub_heading=”e.g. M85049/88-11W03″]

| Basic part number | Locking? | Shell size | Plating | Entry size | ||||

| M85049/88 | Straight | – | non-self-locking | e.g. 11 | W | cadmium olive drab | 02 | **actual entry size is dependent on shell size |

| M85049/89 | 45 degree | N | self-locking, non-detented | A | black anodised | 03 | ||

| M85049/90 | 90 degree | S | self-locking, detented | N | electroless nickel | |||

“N” Self-Locking, Non-Detented, utilizes an internal captivated anti-decoupling device (Self-Seating) with no audible clicking mechanism.

“S” Self-Locking, Detented, utilizes an audible detented anti-decoupling device.[/ultimate_info_table]

| Shell size | 02 | 03 |

| 09 | x | 6.4 |

| 11 | x | 7.9 |

| 13 | 7.9 | 11.1 |

| 15 | 11.1 | 14.3 |

| 17 | 12.7 | 15.9 |

| 19 | 15.9 | 19.1 |

| 21 | 15.9 | 20.6 |

| 23 | 17.5 | 23.8 |

| 25 | 19.1 | 25.4 |

[/ultimate_info_table]